The production process of beds for FAT lathes

Constructing FAT lathes is a complex and complicated process. One of the main elements of the construction of our machines are beds, which are first made in the foundry.

FAT HACO delivered a bed model to PGO S.A. Iron Foundry Branch in Śrem, which made a cast of unusual dimensions in the LOST FOAM technology. It is a full mold technology using a polystyrene (EPS) model. It consists in burning a styrofoam model by liquid metal poured into a mold. At the same time, the target shape of the casting is created.

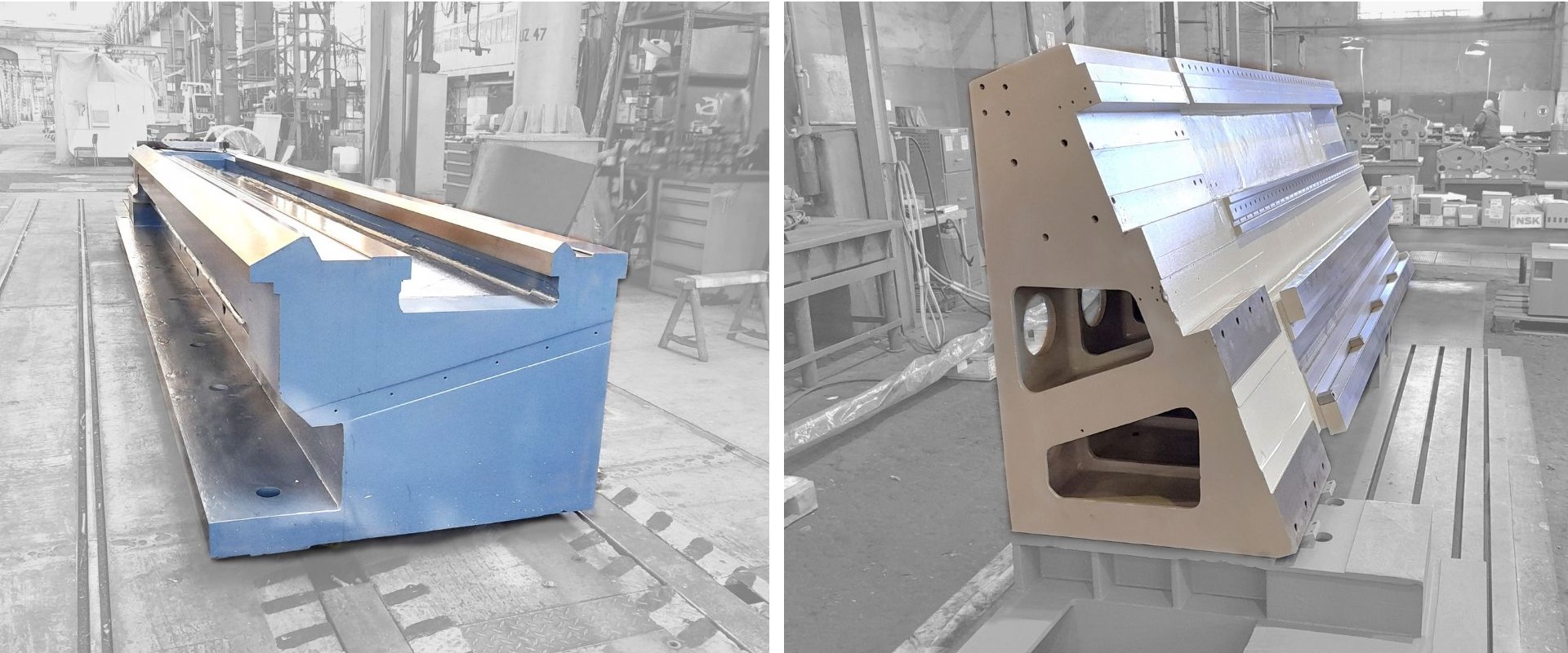

The casting of the slant bed for the FCT lathe shown in the video below is almost 7 m long and weighs over 7 tons, which makes it one of the largest castings made in the LOST FOAM technology.

The process of creating a cast bed for FAT lathes

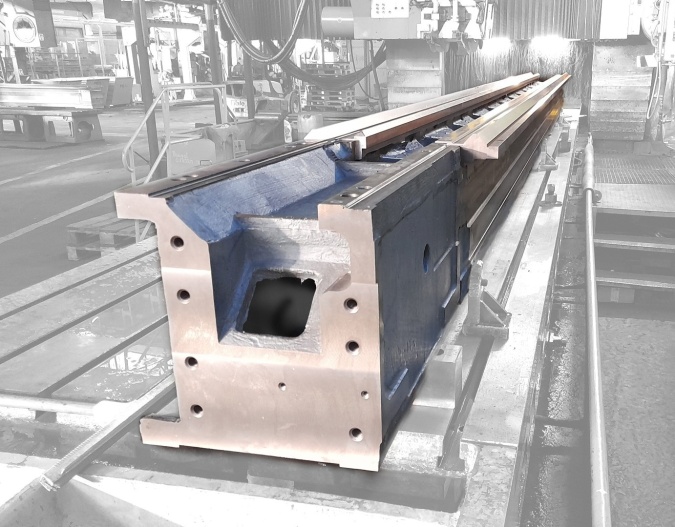

The finished bed cast is then sent to our plant, where it is subjected to precise milling, induction hardening and grinding. The video below shows the technological process of producing a bed for the TUR SMN lathe.

Bed grinding process at Fabryka Automatów Tokarskich we Wrocławiu

FAT lathes, due to their design and purpose, are divided into machines with a flat bed and slant bed. Special, mono-block type bed made of cast iron is a rigid structure which perfectly absorbs vibrations. Extra wide, deeply hardened and ground guide ways ensure precise machining of huge work pieces and excellent surface quality. All of the above guarantee long-life accurate operation of the lathe.

Flat bed Slant bed