CNC turning - what is it?

Metal turning is one of the forms of machining, which involves the production of elements with a cylindrical shape. As a result of metal turning, a wide range of elements can be produced, from simple shafts, sleeves, to more advanced products, by combining external and internal machining.

With the development of technology, FAT HACO has focused on CNC numerically controlled lathes in its offer. Thanks to them, turning of metals and other materials becomes faster while maintaining much higher precision and surface quality. CNC turning itself consists in removing metal shavings (machining) from the object rotating in the chuck with the use of turning tools.

- The work of a lathe can be divided according to the way of surface machining. And so we distinguish:

External turning (the outer surface of the workpiece is machined)

External turning (the outer surface of the workpiece is machined)

Internal turning (the inner surface is machined by boring bar)

Internal turning (the inner surface is machined by boring bar)

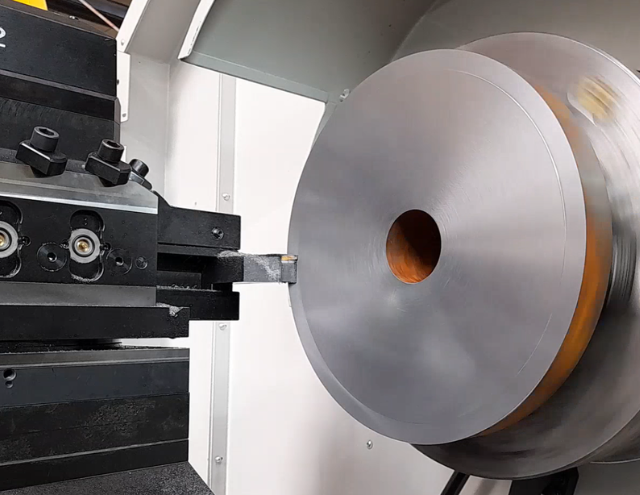

Face turning (machining of the workpiece from the front, i.e. the opposite side of the lathe spindle)

Face turning (machining of the workpiece from the front, i.e. the opposite side of the lathe spindle)

Metal machining in a lathe – turning process

The lathe is used to machine the workpiece rotating in the chuck. For long workpiece is mounted between the chuck and the tailstock. The lathe was designed for the production of cylindrical elements. The workpiece must be mounted on the lathe spindle in such a way that it is balanced as much as possible (that is, when rotating, it generates the smallest runout).

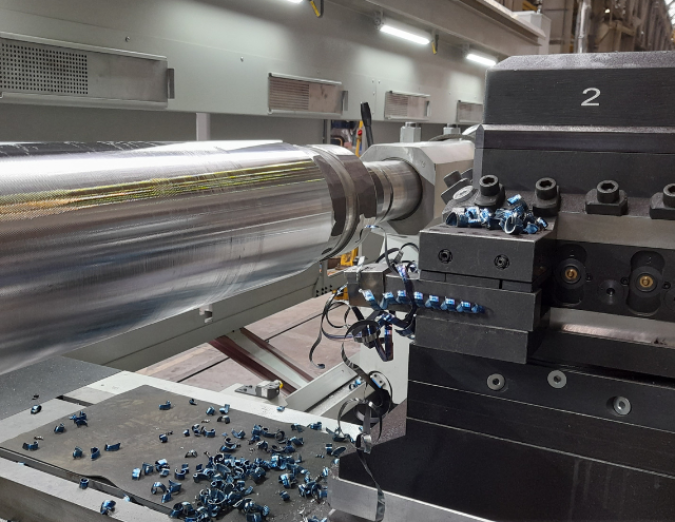

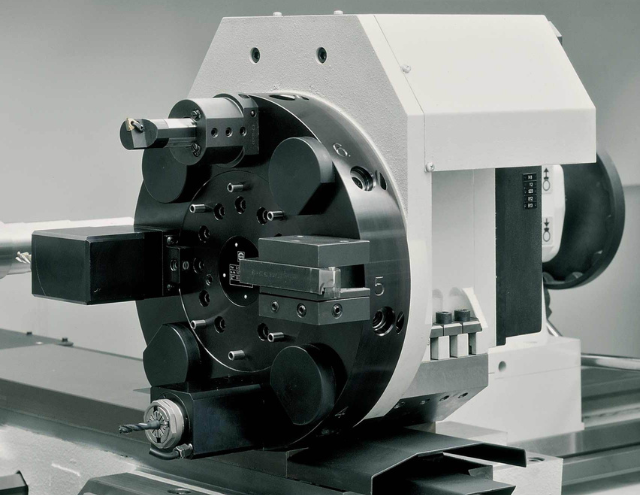

Once the solid rotates smoothly, the turret is given the appropriate speed for rough machining, which removes excess material and allows the rotational speed (RPM) to be increased.

Rough machining on Lathe TUR MN 1150

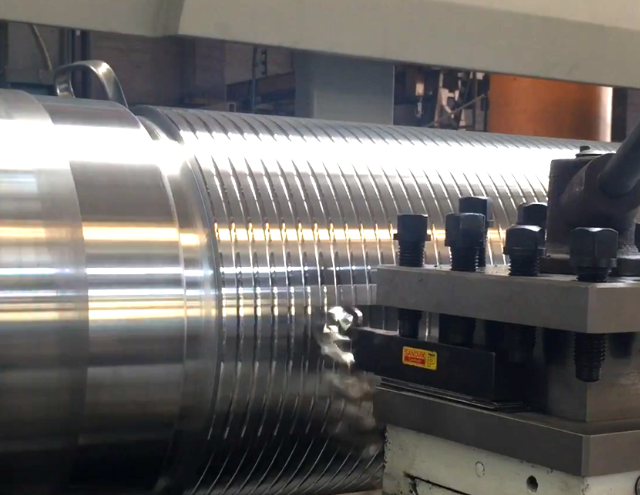

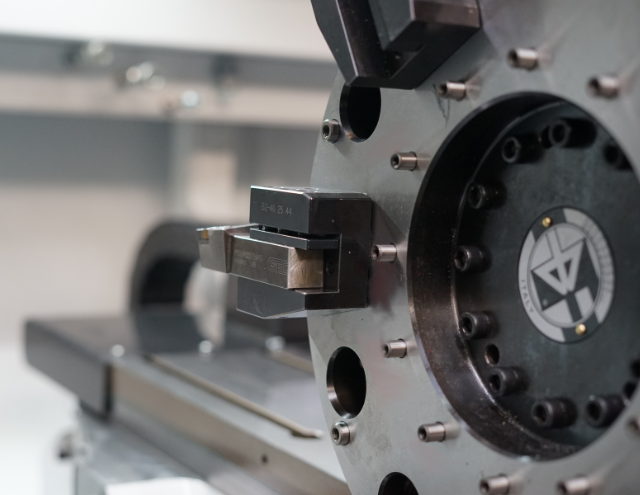

Cutting metal in a lathe is done with various types of turning tools. Drills and thread forming tools are common in CNC turning. The end of the machining process is crowned with finishing machining, which gives the object its final shape and the required surface quality.

Finishing machining on Lathe TUR MN 1100

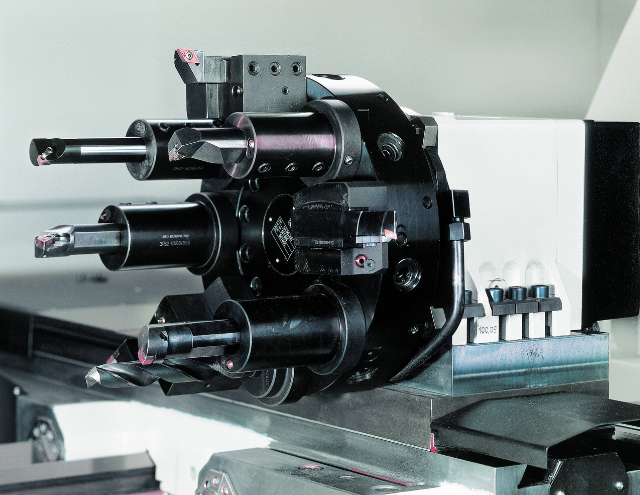

After machining, the workpiece is removed from the chuck or cut off with other tools. The result of the lathe's work is the production of an element with the required physical parameters, ready for possible further machining. Metal machining is a very broad topic and requires knowledge of the subject and the skills of the lathe operator. Turning steel, aluminum or titanium alloys is associated with the machining properties of these materials. They require the selection of appropriate tools, i.e. types of turning knives and the speed of the turning process itself. Numerical control allows you to perform other operations on lathes. Using rotating tools and an interpolating spindle, you can mill, drill, grind, and perform more complex contouring.

Turrets with driven tools

Today, CNC turning is increasingly used, among others, in industrial production, agriculture, the automotive industry and the furniture industry. The industrial revolution of the 19th century gave great importance to machining and to this day it is the most common way of shaping metals. The emergence of computerized, numerically controlled machines confirms our belief that machining will continue to develop. In turn, Industry 4.0 and the widespread connection of machines to the network opens the machining industry to completely new horizons of working with CNC machines.

The evolution of CNC lathes over the years, manufactured by FAT. Photo gallery below: