CNC lathe service

Service of CNC lathes is extremely important to maintain the efficiency and performance of these advanced machines. Here are some basic information and tips for servicing CNC machines

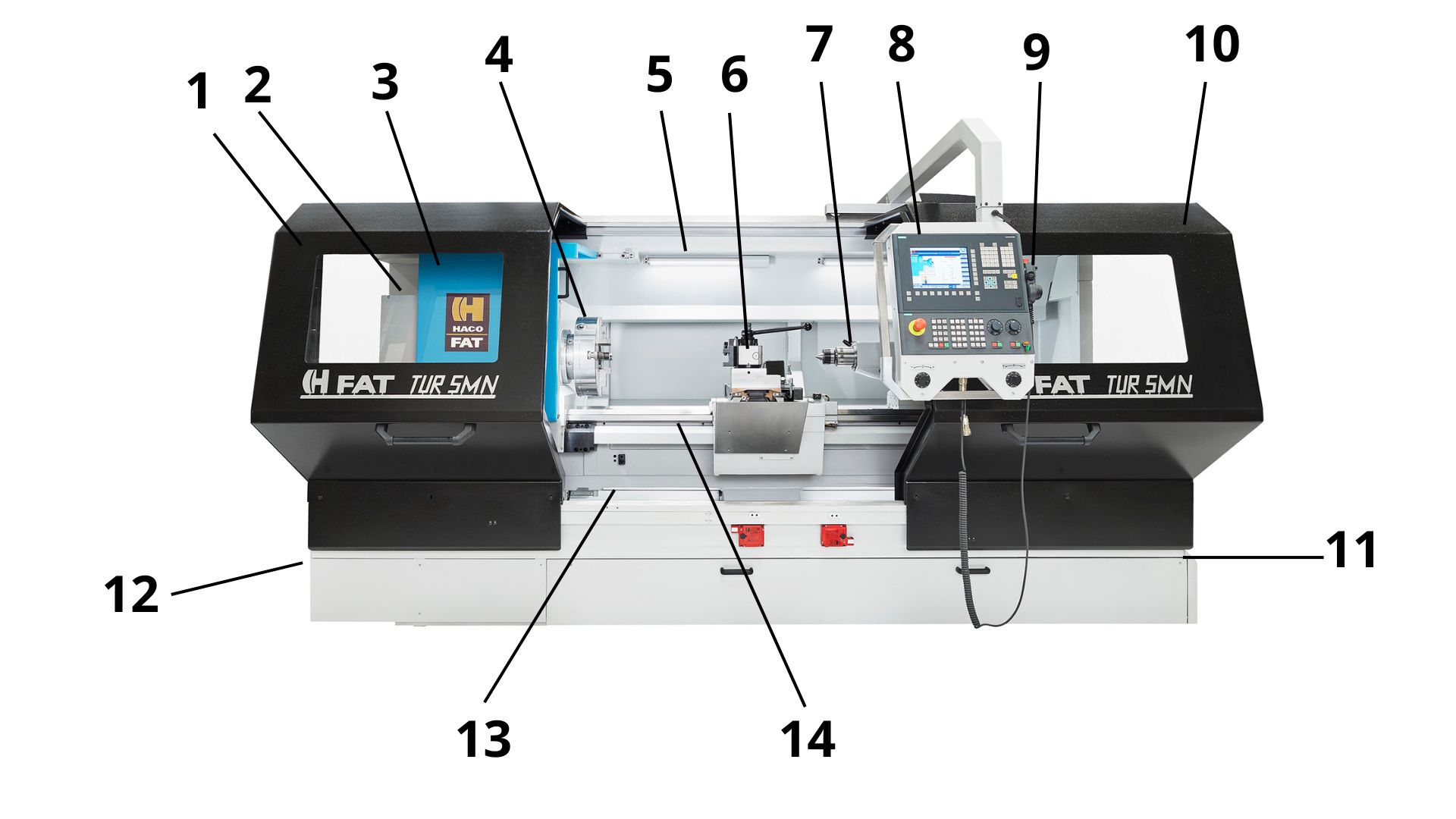

Construction of lathe TUR SMN 630

- Left guard

- Headstock

- Additional cover-chuck guard

- Chuck

- Lamp

- Turret

- Tailstock

- Operator panel

- Thirdwheel

- Right guard

- Coolant pump and chip conveyor electrical connections

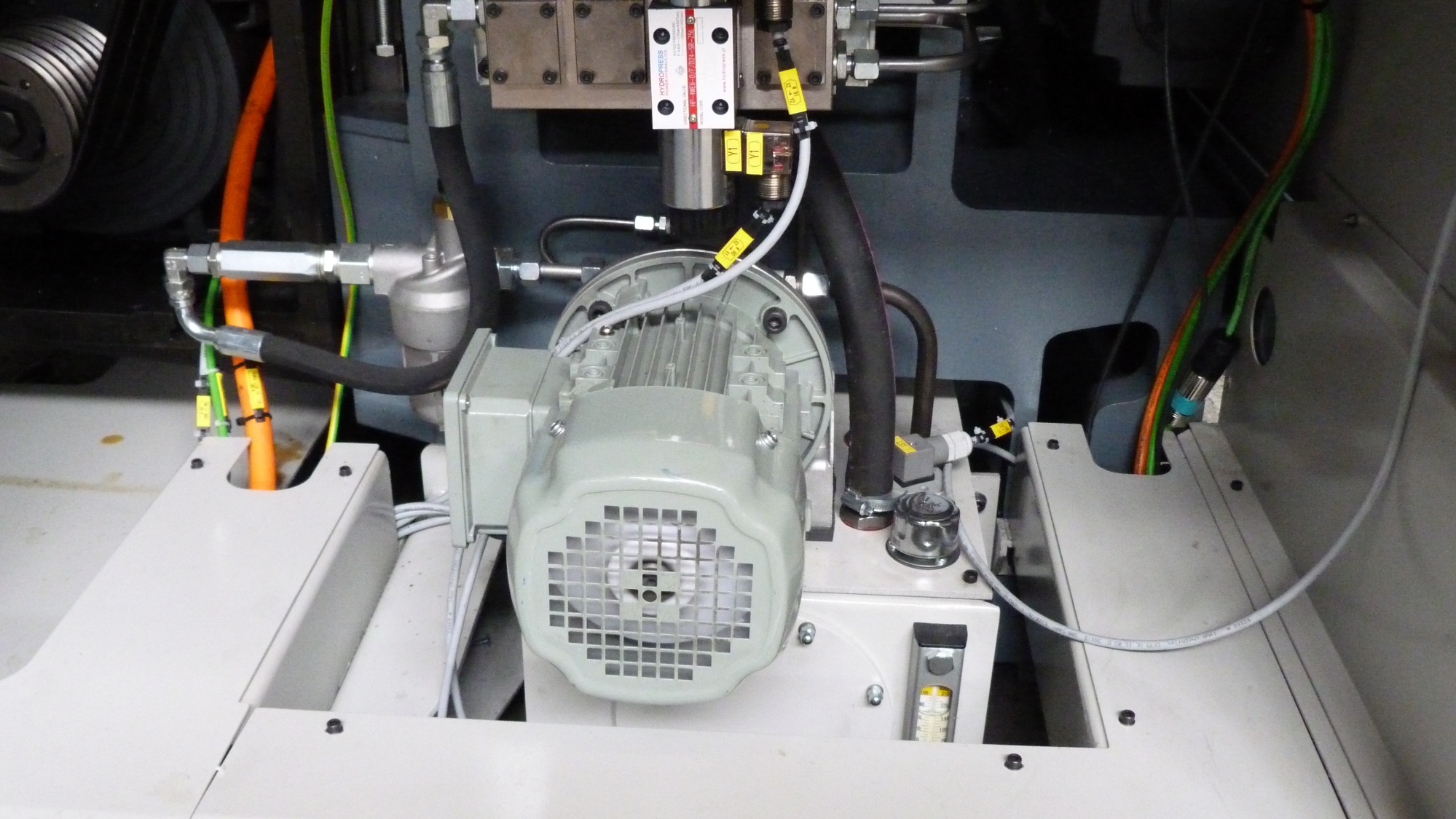

- Main motor area access door

- Bed

- Guides

Preventive maintenance

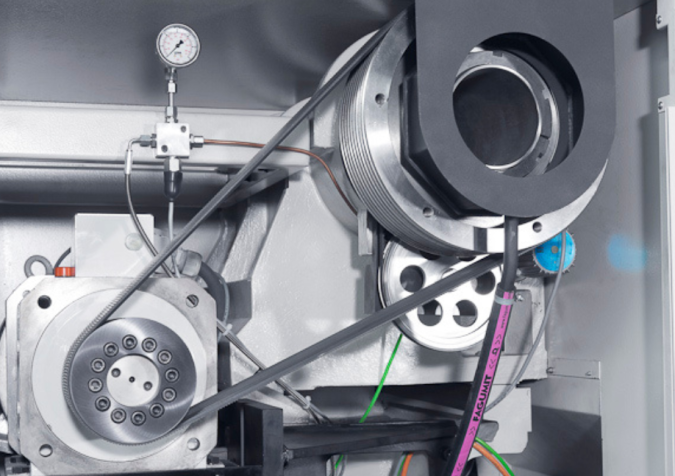

Regular inspections and preventive maintenance are key to keeping your CNC lathes in good condition. Oils, greases and filters should be regularly checked and replaced, and various components such as guides, ball screws and encoders should be thoroughly cleaned and inspected. Proper lubrication is a necessary element for the good functioning and long service life of the machine tool. The lathe should be checked for proper lubrication before each start-up and periodically during machine operation. The machine tool has two integrated lubrication systems. The first lubrication system is placed at the end of the bed and supplies the guide bed. A second lubrication system is placed under the headstock and supplies the headstock.

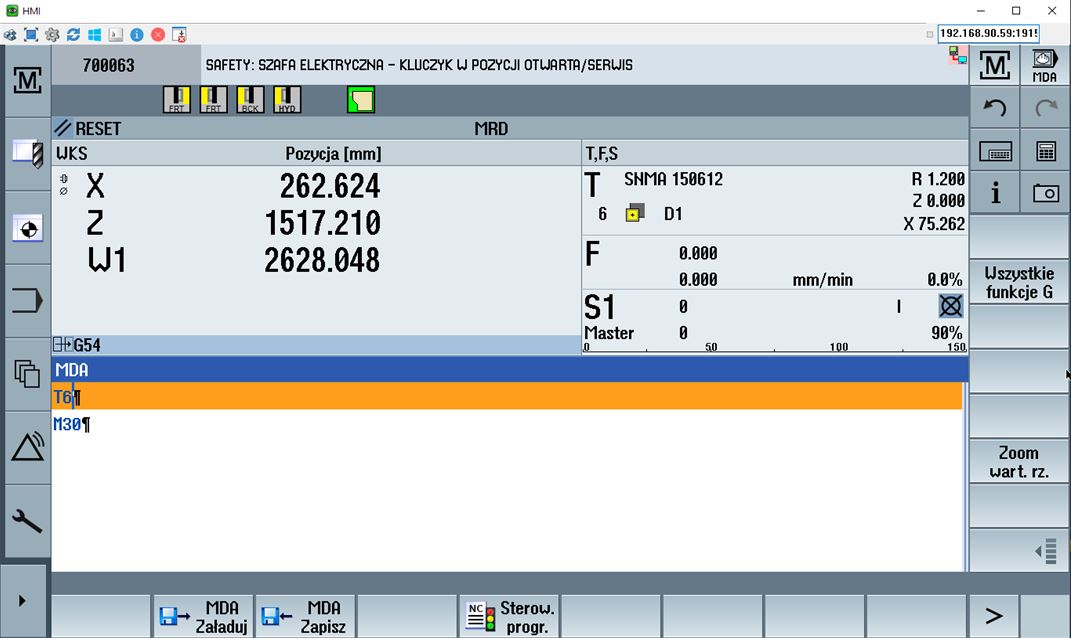

Diagnostics and repair

In case of CNC lathe failure, it is necessary to carry out diagnostics to locate the problem. Servicers must be able to analyse fault logs, check electrical connections and perform functional tests. Once the problem is located, it is necessary to repair or replace the damaged components.

Calibration and settings

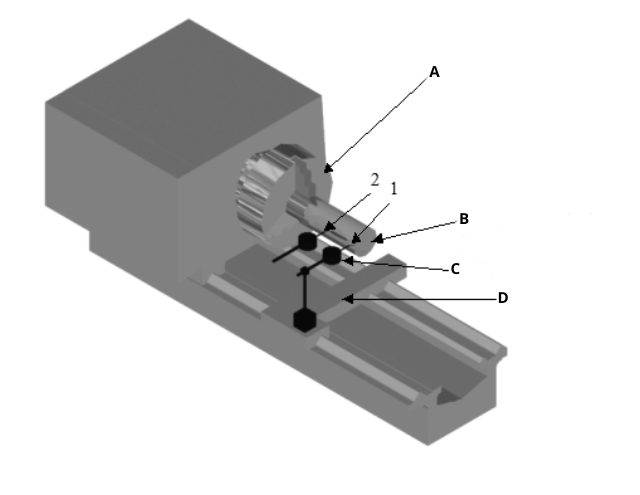

CNC machines need to be updated regularly to ensure machining accuracy. Calibration includes checking and adjusting settings for geometry, axis positioning, measurement accuracy and error compensation. If there is a misalignment of the alignment with the tool or for other reasons, the alignment is as follows:

- Clamp a round test piece about 100 mm (4 in.) in diameter by 300 mm (12 in.) in length in the chuck and carry out OD turning.

- Measure the cylindricity of the cut piece using a dial indicator as shown above to determine whether the front end of the test piece is thinner or thicker than the back end, if cylindricity is not within allowable tolerance adjust as follows:

- Place the dial indicator stem at the front of the test piece and set its reading to zero.

- Adjust alignment using levelling bushings A and B. If the test piece shows decreasing taper, move the headstock away from the toolpost, if the test piece shows increasing taper move the headstock toward the toolpost.

- Secure the nut on anchor bolts tightly. Then tighten the two levelling bushings evenly

- Read the dial indicator to determine whether the headstock has been moved by the required amount. The reading may vary depending on the torque at the leveling bushings.

- Carry out OD turning again, repeat the above steps until accuracy is within allowable tolerances.

Software updates

CNC lathe control software can be updated regularly to make improvements, improve performance or solve compatibility issues. Servicers may install these updates and perform appropriate tests to ensure the machine is functioning properly after the update.

Training and support

Service personnel should be properly trained in the area of CNC machine operation and repair. FAT HACO provides technical support to users of their CNC machines to help them solve problems and make optimal use of the machines. It is worth following the manufacturer's recommendations for maintenance and service on a regular basis to keep the machine in the best possible condition. If you are interested in servicing your machine, please contact us.