Polish CNC machines in the Philippines

CNC lathes manufactured by FAT HACO find their customers all over the world. We can boast that they even reach such remote countries of the world as the Philippines. We recently refreshed our contact with Indexss (International Drilling Exploration Supply And Services, Incorporated) who has been using our machines for more than 11 years. By focusing on responsible relations with contractors, we try to provide professional support even in hard-to-reach places.

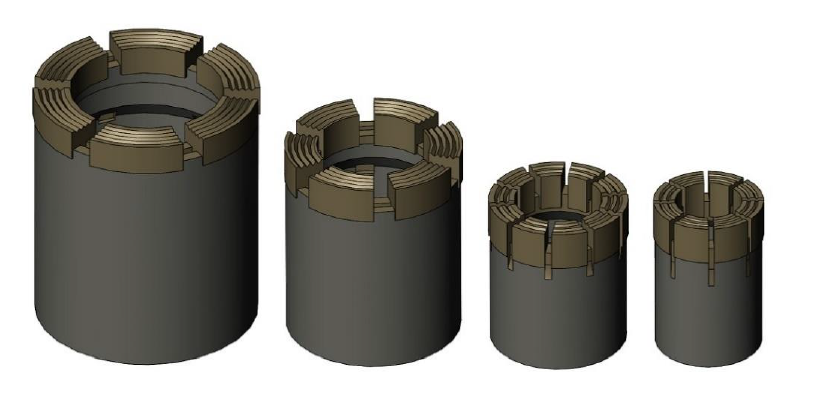

Indexss was founded in 2012 by a group of international, drilling rig operators, manufacturers and owners with more than 30 years of experience in the drilling, drilling and rig manufacturing industry. Indexss mission is to manufacture, source and supply a wide range of drilling tools and consumables for the international drilling industry.

In modern manufacturing plants located in the Clark Freeport zone in the Philippines, Indexss manufactures and supplies purpose-built drilling rigs and tools for drilling rigs used in the mining, extractive, civil and petroleum industries. Today, the company delivers its products and services to several regions, including Asia, Australia, Europe and the Middle East. We talk about cooperation with FAT HACO with Mr. Marc Godwin, general manager of Indexss plant in the Philippines.

- What is the profile of your company? What Indexss are doing and produces?

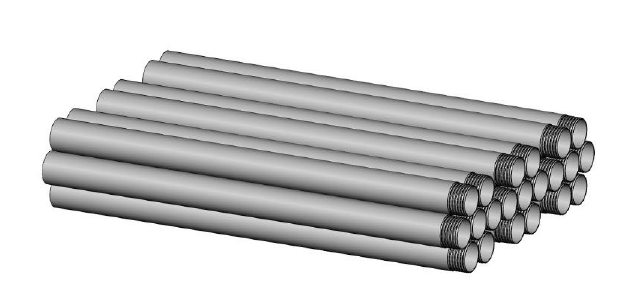

Marc Godwin: Indexss is in the business of design and manufacturing of drilling tools and consumables including drill rods for the mineral exploration sector of the world mining business. Indexss supplies these parts and consumables to the drilling contractors who work for the exploration industry.

- How the cooperation with Fat Haco began?

M.C.: I believe the start was due to Fat Haco machines were being used in the similar industry and they were chosen based on this.

- What types of machines were you looking for?

M.C.: They required machines to primarly be able to machine the threads on the drill rods, and so the thru bore diameter was of great importance as the tubes need to pass thru the headstock into the chuck with a rear chuck to hold them from wipping due to the 3m total length.

CNC lathe TUR 630 MN with second spindle nose

- And what decided that you choosed FAT HACO lathes?

M.C.: As per above, i believe it was due to the fact they were being used for similar process.

- What are you doing exactly on these machines?

M.C.: Primarly they are used for machining tubular raw materials into Diamond Drilling Rods and secondly they are used to machine some bigger parts for the tooling used for drilling.

- Which models do you have?

M.C.: TUR 630A MN (2012)

- What is the destiny of our machines in your business?

M.C.: These machines will continue to be used for manufacture of the tubular products into the forseable future, until such time as they can no longer be used efficiently.

- How do you rate our machines?

M.C.: These two machines have performed exceptionally well over the 11 years of life, our only problems have been the fact that there is no local suport for the Siemens OS and the delay in product support due to the factory being in Europe, so it takes time to get responces back to questions etc. Parts suport has been fairly good...