Export of new CNC lathes

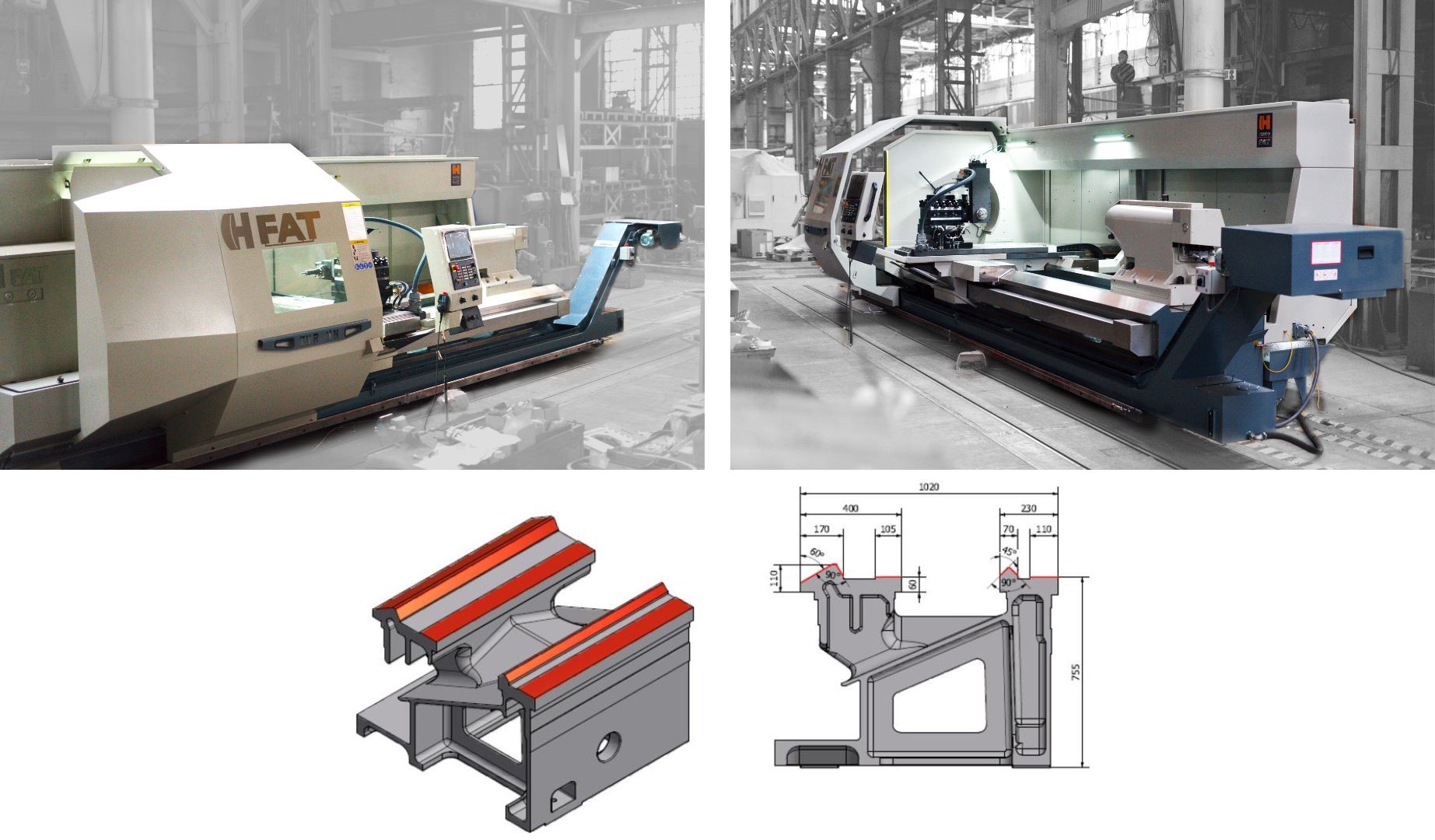

FAT HACO exports more CNC machines. Our lathes are recognized all over the world. This time we produced two impressive machines for a client from Uruguay: TUR MN 1150 and TUR 3MN.

THE INTENSIVE END OF LAST YEAR ABOUNDED WITH THE IMPLEMENTATION OF TWO LARGE CNC LATHES: TUR MN 1150 AND TUR 3MN.

TUR MN 1150 lathe is designed for machining heavy components up to 1150 mm in diameter. This series offers manufacturers heavy duty machining with the guarantee of durability, precision and stability. Special, mono-block type bed made of cast iron is a rigid structure which perfectly absorbs vibrations. Extra wide, deeply hardened and ground guide ways ensure precise machining of huge work pieces and excellent surface quality. All of the above guarantee long-life accurate operation of the lathe.

Equipment of TUR MN 1150:

- Siemens Sinumerik One

- Third MPG portable handwheel

- Automatic programmable gearbox

- 4 position automatic tool turret

- Steady rests

- Complete installation of coolant supply

- One movable front door (connected to cross slide)

- Sliding rear guard

- Hydraulic tailstock quill

- Hydraulic aggregate

- Central lubrication system

- Front chip conveyor

- Direct linear scale for „Z” axis for machines

with a turning length over 5,000 mm - Absolute encoders of axial motors

- USB port

- Annual Siemens service contract

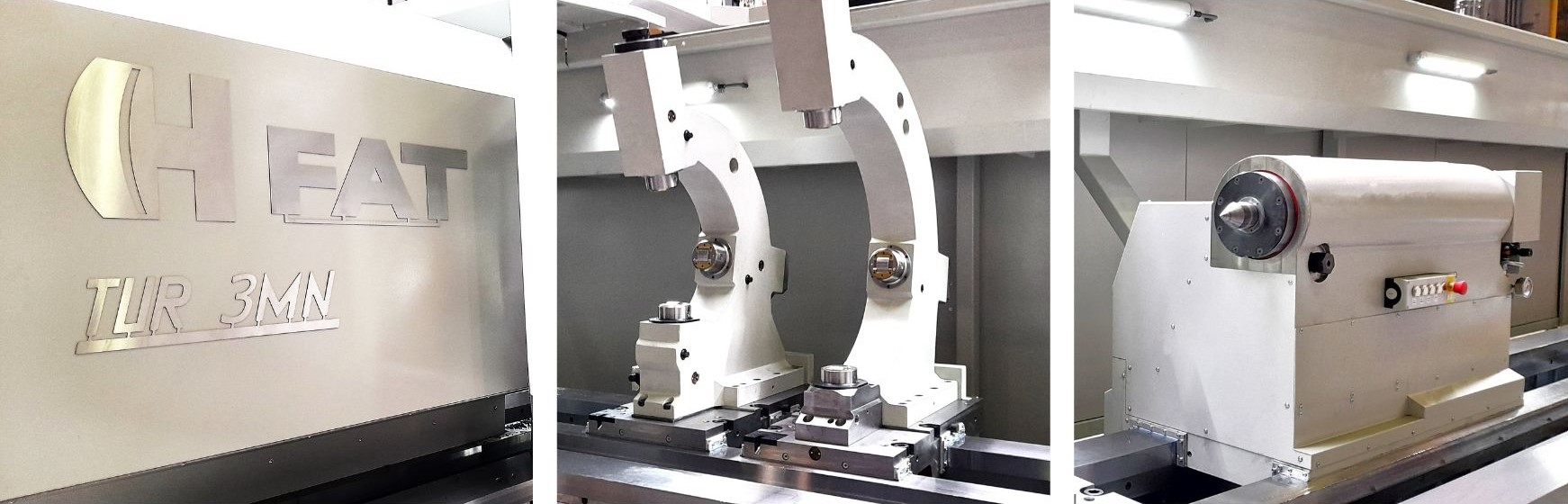

Heavy 4-guideways lathe TUR 3MN is based on a single mono-bloc casting bed design incorporating 60Rc hardened and ground steel inserts, assembled using “Guide Easy FIX” technology. This enables easy guideway removal and refurbishment if ever necessary.

Equipment of TUR 3MN:

- Siemens Sinumerik One

- Third handwheel (MPG)

- Automatic programmable gearbox

- 4 position automatic tool turret

- Steady rests Type C

- Complete coolant system

- One movable front door (connected to cross slide)

- Full length rear guard

- Tailstock with hydraulic quill

- Chip conveyor

- Rotary control panel

- Absolute encoders of axial motors

BELOW PHOTO GALLERY OF MACHINE LOADING