21 August 2023

Machining of gear wheels

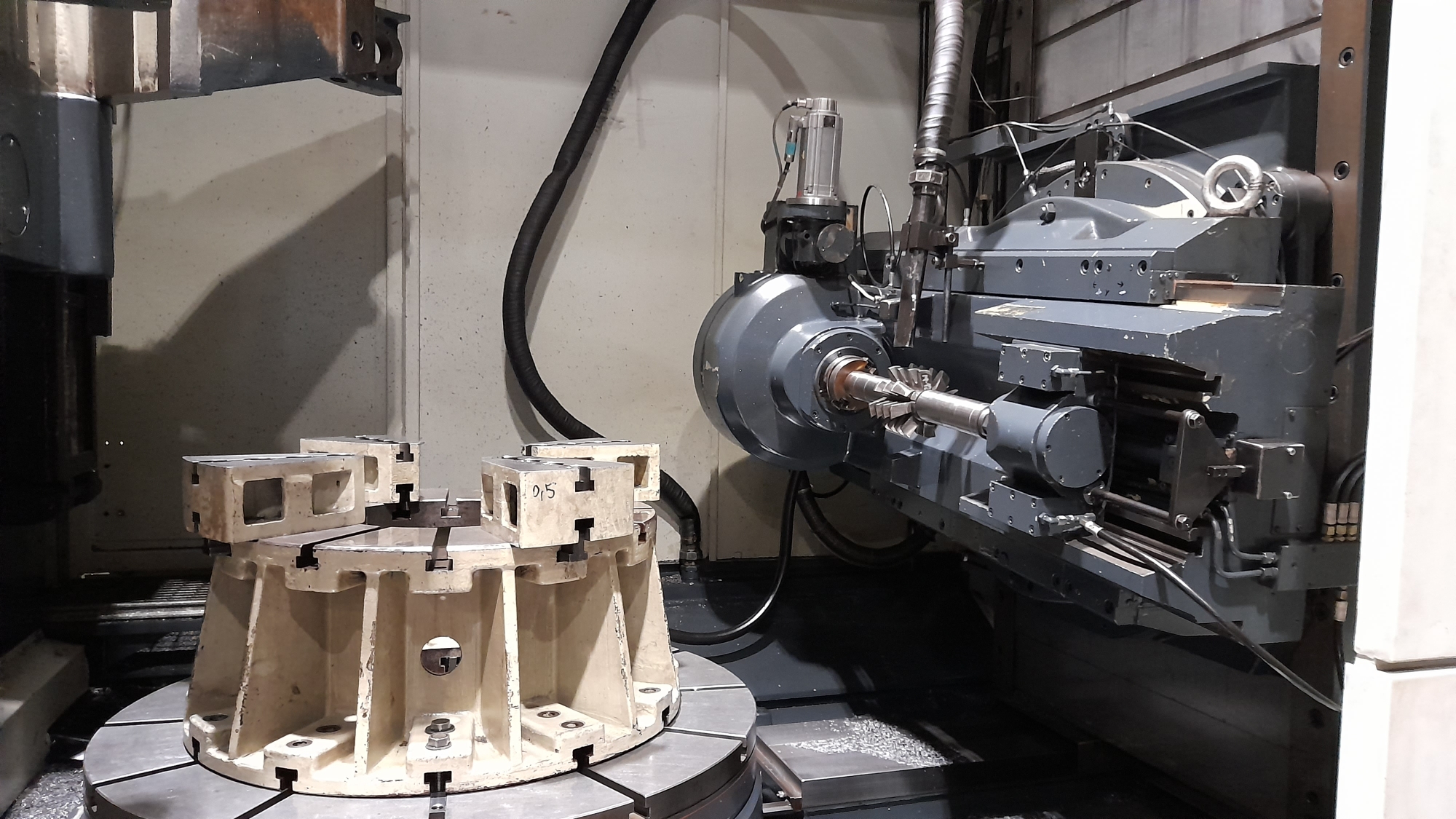

In addition to machine building, FAT HACO also provides milling and grinding of gear wheels for external companies.

Gear wheels machining is a manufacturing process that aims to create precise and coordinated teeth on gear wheels. Gears are often used in mechanisms and machines to transmit motion and torque between axes. One of our leading clients is BEFARED Spółka Akcyjna.

Here are some of the techniques used by FAT HACO in the machining of gear wheels:

- Milling: It is a process in which teeth are cut with modular cutters on the cylindrical surface of the gear wheel. We use a special envelope milling machine with CNC control. We also make gear wheels with external/internal teeth on Fellows chisels.

- Grinding: It is used to obtain very high precision and quality teeth surface. The wheels are grinded by the shape method on the grinder, which gently removes the material from the teeth until the required precision and finish is achieved.

- Measurement and control: After machinning, the gear is measured and checked for dimensions, surface quality, tooth shape and possible deviations from the assumed design parameters. We provide measurement services on the Carl Zeiss Accura 2 coordinate measuring machine. Check more about measuring probe.

Machining of gear wheels is a complex process requiring advanced skills and specialized equipment. Precision and quality are key to ensure efficient and reliable operation of the gear in mechanisms and machines. If you are interested in machining gears please contact us.

KomentarzeDodaj komentarz