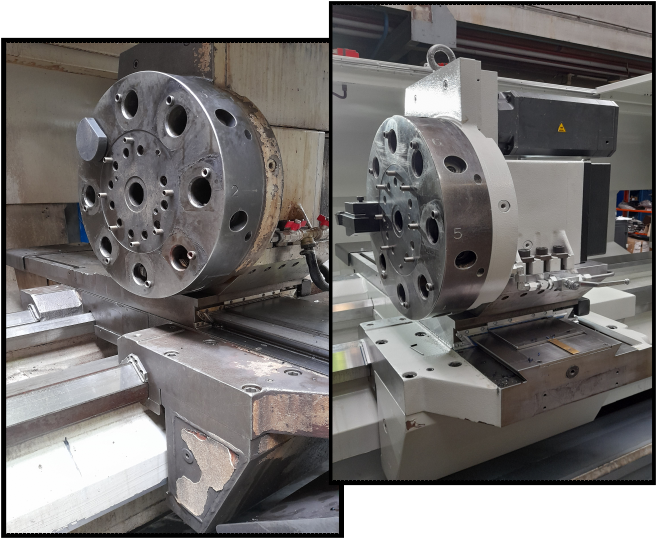

CNC lathe TUR MN 800 – comprehensive renovation

Renovation of a CNC lathe is always necessary to keep the machine in good technical condition, ensure high quality machining and adapt it to changing needs and production requirements.

CNC lathe with a turning length of 3000 mm from 2006.

For FAMUR, we carried out a comprehensive renovation of our CNC lathe, which requires technical experience and knowledge of the specific nature of the machine and its operation. It is important to carry out the renovation in accordance with the manufacturer's recommendations and to follow best practices in the maintenance and repair of CNC machines.

Grinding the bed, renovating the sledge and drawer, cleaning the electrical cabinet, replacing the ball screw are just some of the operations this machine has undergone. Reassembly, geometry and tests confirm the customer's belief that CNC lathes from FAT HACO are reliable and durable even after many years of intensive use

Examples of lathe repair operations:

- Cleaning the electrical cabinet

- Grinding the bed

- Cleaning and inspection of the tailstock

- Replacement of the head base

- Ball screw replacement

- Painting machine