Cutting of aluminum and metal profiles Mubea Systems Profile Flex - professional CNC machines

In our machinery park, we develop the production of specialized machines from the Mubea Systems series.

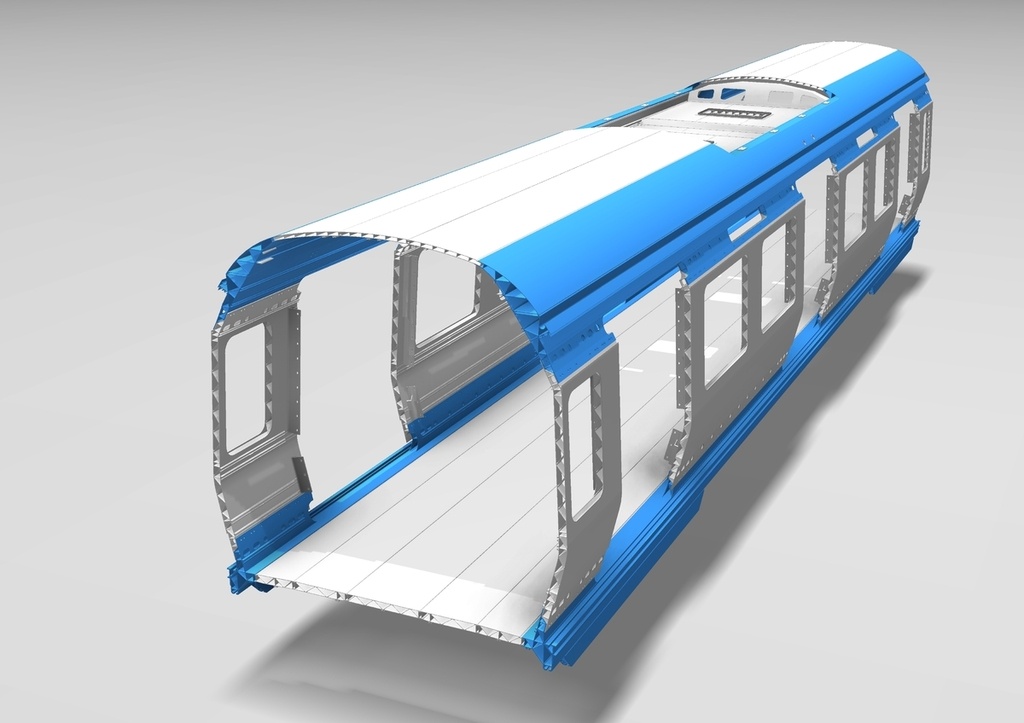

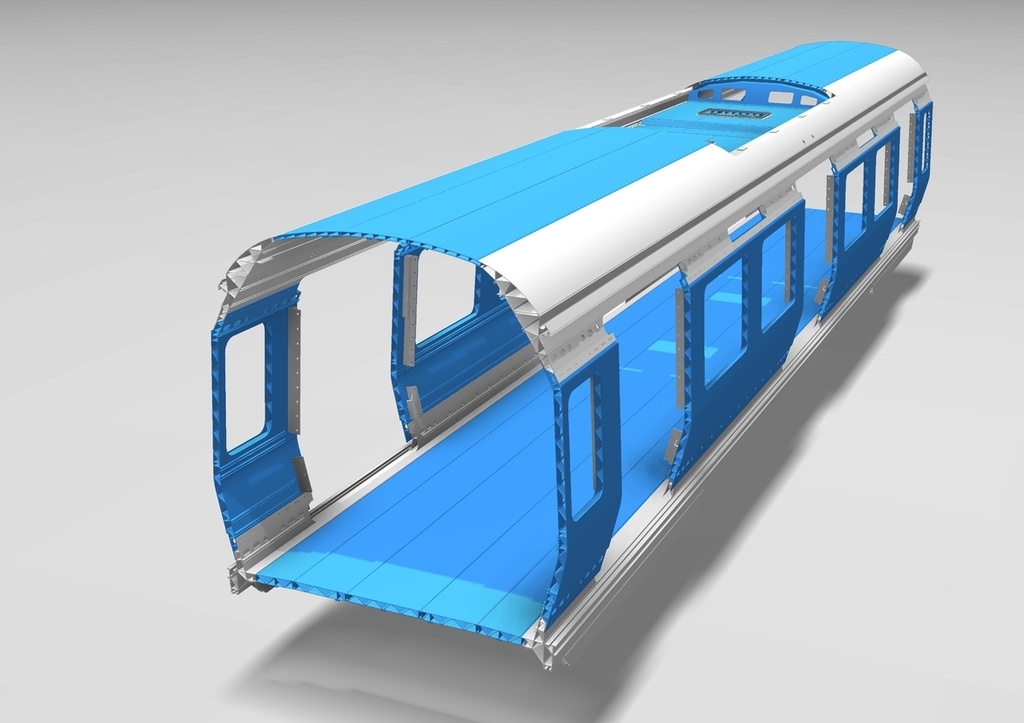

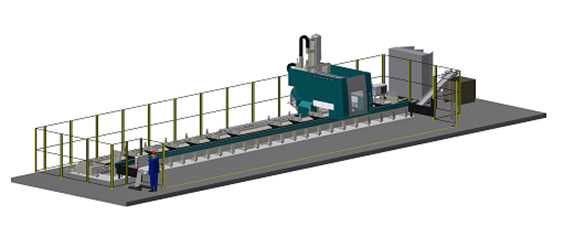

Mubea Systems by HACO is a range of 5 axis CNC machining centers, specially designed for automatic machining of extremely long aluminum and steel profiles. These machines have a wide range of applications in the rapidly developing public transport market, including: railways and aviation. They are used, among other things, to form passenger cabins.

The sections that Profile Flex can handle perfectly are marked here in blue (above). The machine is selected depending on the size of the profile cross-section, that we want to cut. For larger batches, we choose a machine from the Multi Flex or Mega Flex series (below).

Mubea Systems is the only company in the world that has the 4 important key-points of industrial cutting of aluminum profiles or constructions consisting of aluminum and metal profiles under their own control where no external companies are involved:

- 5-axis Machining Single Head or Twin Head up to 30 or 60 meters long and 3.5 meter wide.

- Moveable Clamps with X-axis or, with an individual servo motor.

- Profile Software Pyramid 3D with optional 5-axis cutting.

- Probe Measuring (up to 3 measure points) to recalculate the program instantly in translation and rotation.

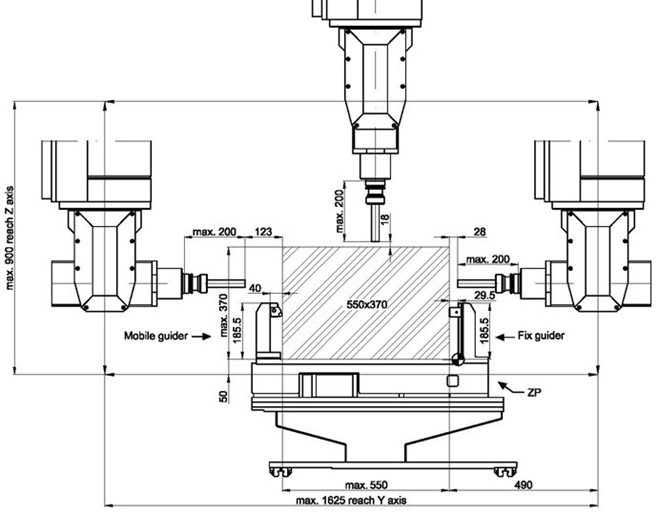

PROFILE - FLEX / X15250 /Y550 /Z370 / SINGLE HEAD – Machine specification

- Work piece Length = 15.250 mm Travel in X = 16.250 mm

- Work piece Width = 550 mm Travel in Y = 1.625 mm

- Work piece Height = 370 mm Travel in Z = 900 mm

AXES SPECIFICATION

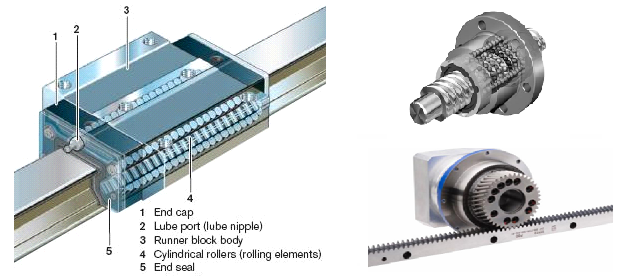

- Travel in X - 16.250 mm - max. 80 m / min - 1.0 m / s²

- rack and pinion - Module 3

- size guides 35 mm

- Travel in Y - 1.625 mm - max. 60 m / min - 1.5 m / s²

- ballscrew diameter 32/20 mm

- size guides 35 mm

- Travel in Z - 900 mm - max. 60 m / min - 1.5 m / s²

- ballscrew diameter 32/20 mm

- size guides 35 mm

All axes are built with long version linear guides with cylinders.

CE REGULATION & SAFETY

All our machines are built following CE regulations. Safety is prior for Mubea Systems. All our machines are delivered with:

- Safety fences around the machine

- Safety led's to protect the loading and unloading area

DIMENSIONS & WEIGHT

- Dimensions Safety Fences without lifting chip conveyer = 22.990 mm x 6.070 mm

- Dimensions Safety Fences including lifting chip conveyer = 23.620 mm x 6.070 mm

- Height of the machine = 4.200 mm

- 20.500 Kg

LUBRICATION

- Automatic centralized lubrication system linear guides of X-, Y- and Z-axis

- Automatic centralized lubrication system rack and pinion for X-axis

- Automatic centralized lubrication system ballscrew of Y and Z-axis

AIR CONSUMPTION

- Flow of 400 Liters / minute at 8 bar (kg/cm²)

MUBEA 'S FEATURES HIGHLIGHT

- All mechanical parts are made in the HACO GROUP

- Linear roller guides for main axes X, Y and Z

- Planetary gear boxes with rack and pinion ALPHA

- Ball screws of REXROTH

- Bearings of SKF

- High machine accuracy compensated by Laser Tracker Control

- MQL - Tool lubrication system

- Pneumatic material FESTO or NORGREN

- Security systems of SICK

- SINUMERIC ONE Numeric Controller with Service Contract up to 5 years

- Temperature compensation especially for long machines and long pieces

- MDynamics with Tool Center Point programming (Full 5-A-axis)

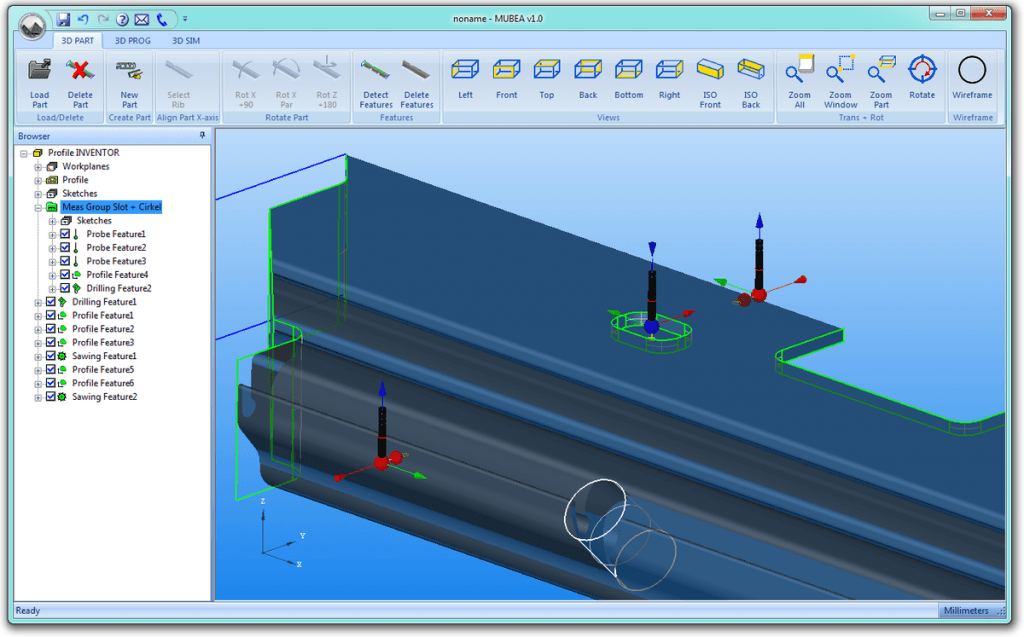

- PYRAMID 3D, by MUBEA developed software for machining profiles

- Measuring software up to 3 measure points to compensate the zero point of the operation

- Measuring software to make contour corrections (MMPC)

- Solutions for Curved Profiles

MUBEA PYRAMID 3D SOFTWARE IS SPECIALLY DEVELOPED FOR FINISHING PROFILES

![panel_cnc.[1]](https://www.fathaco.com/files_tiny/panel_cnc.[1].jpg)

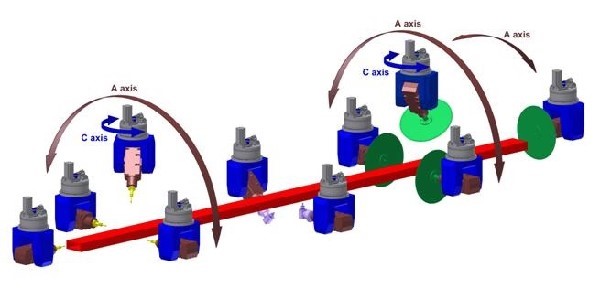

All Mubea's 5-axis machining centers are fully 5-axis. All axes are servo driven and programmable. This does not means you are able to cut everything you want. The basic version of the Pyramid 3D is a 3 + 2 software. This means that the spindle and fork, the A- & C-axis, never turn during cutting. They take position before the tool starts to cut.

Main features of Pyramid 3D software

- Automatic detection of all individual functions

- Automatic detection of identical features

- 3D simulation with collision check and time calculation

- Automatic calculation of terminal positioning

- Automatic group creation

- Automatic selection of functions and groups for creating macros

- Automatic creation of measurement groups

- Automatic detection of identical feature groups

Optional Mubea has Pyramid 3D - Chamfers and ruled surfaces. This option is using the Siemens option "MDynamics" which contains:

- Tool length compensation in 3D

- Tool radius compensation in 3D

- Tool Center Point programming ( TCP ) - TRAORI and much more

Mubea Systems software simulation

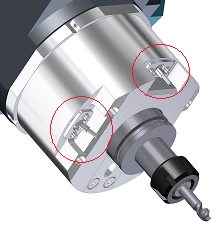

MILLING HEAD OF 18 KW (S6) | HSK-F63 | A-axis & C-axis | Fork MUB04

SPINDLE

- Water cooled spindle of 18 kW – max. 24.000 rpm

- Tool holder type is HSK-F63

- Long spindle nose for easy milling between clamps

A-AXIS - TILTING OF SPINDLE

- A-axis - CNC rotation of the spindle -120° +120°

- A-axis - CNC rotation speed of 50°/ sec.

C-AXIS - TURNING FORK

- C-axis - CNC rotation of the fork -215° +215°

- C-axis - CNC rotation speed of 50° / sec.

TOTAL ELECTRICAL POWER 50 Hz

- 3 x 400 V ±5% AC + N

- 36.0 KVA

LUBRICATION SYSTEM & ADAPTION ANGULAR TOOLS

One block is mounted over the long nose for 3 reasons:

- Center pin for adaption and orientation of angular tools

- Canalization of the air and oil to lubricate the tools

- The 3 nozzles are individual orientable

PNEUMATIC CLOSED COUNTER BALANCE SYSTEM

- 2 large pneumatic cylinders

- Tank of 100 liters

- Closed pneumatic system

- Reduce air consumption to a minimum

- Due closed system high Z-axis speed possible

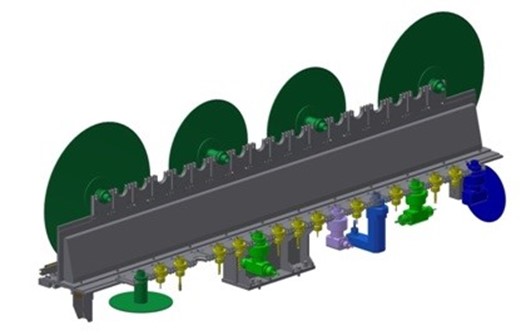

TOOL MAGAZINE OF 36 STATIONS TRAVELING WITH THE COLUMN (X-AXIS)

There are 18 vertical and 18 horizontal places available. Tool change time is between 8 and 10 seconds.

18 VERTICAL PLACES

- All standard tools - maximum tool diameter 280 mm

- All kind of angular tool holders

- Maximum tool length of 200 mm

18 VERTICAL PLACES

- All standard tools - maximum tool diameter 520 mm

- No angular tool holders allowed

- Maximum tool length of 200 mm

Pay attention that large tools can occupy more than 1 magazine place.

REACHES OF MACHINING

All reaches are shown with following parameters:

- Maximum tool length

- Necessary free movement tolerances

- Standard Jaw Fix and Jaw Var

MACHINE ACCURACY

In production all Mubea machines are assembled and adjusted with an optical laser tracker of Leica in order to guarantee the accuracy of the geometry of the machine. During the installation the optical laser tracker made by Leica is used to re-check the geometry of the machine.

MACHINE ACCURACY CALIBRATE AT 20°C

POSITION ACCURACY

- X-axis: +/- 0.025 mm/m & +/- 0.050 mm / 10m

- Y-axis: +/- 0.025 mm/m

- Z-axis: +/- 0.025 mm/m

REPEATABILITY ACCURACY

- X-axis: +/- 0.025 mm

- Y-axis: +/- 0.025 mm

- Z-axis: +/- 0.025 mm

Mubea only guarantees the geometrical precision, positioning accuracy and repeatability of the machine if the foundation is constructed according to the specifications on the machine layout.

STANDARD ENVIRONMENT TEMPERATURE

- minimum + 10 °C

- maximum + 35° C

LIGHT WORKING AREA OF THE MILLING HEAD

- minimum 300 lux

- maximum 500 lux

MAIN ADVANTAGES OF MACHINE CNC MUBEA SYSTEMS

REDUCED OPERATION COSTS

Because there is no need to move a component from one machine to another and each component can be processed in a single setup, this results in shorter production times and lower manufacturing and component costs.

REDUCTION OF LABOR COSTS

One person can operate the machine compared to conventional machines that require 2 to 3 people. The savings in setup time are significant.

IMPROVED ACCURACY

Machining the element on such high-precision machines eliminates human errors. Greater accuracy means reduced assembly time.

MORE DESIGN FLEXIBILITY

The versatility of the machine and software allows designers to be more creative and allows production departments to develop better assembly techniques. These machines are at the cutting edge of technology and open up new production markets for all users.

Mubea Systems by HACO will provide you with a complete solution for your production than most other profiling machine suppliers. If you are interested in HACO machines, please contact us for more details.

Movie, presentation of machine possiblities