Which CNC lathe choose for your company? Turning diameter, monolithic bed, robust tailstock, headstock

When thinking about buying a CNC machine for your company, we often face a dilemma in which equipment to invest to meet our expectations. Therefore, it is worth paying attention to the value for money and whether the chosen machine model will be suitable for the type of machinning that we do in our plant. Finally, we select the tooling and the necessary components.

The high quality of CNC lathes manufactured by FAT HACO consists of several elements and properties that are worth knowing in order to properly choose the machine from our offer. Below we will discuss the key building elements of FAT HACO lathes and their technical aspects.

Turning diameter

The turning diameter of the lathe is one of the key specifications of the machining machine. It means the maximum size of the workpiece that can be machined on a lathe.The turning diameter depends on the specific lathe model. Typically, manufacturers give two values - swing over bed and swing over saddle.

- The swing over bed diameter is the maximum size of the workpiece that can be placed on the lathe and rotated around the axis. This means that an object of this diameter can only be machined from the forehead. Read more about CNC turning

- The swing over carriage determines the maximum size of the workpiece that can turning when the workpiece is in the extended position. This is usually less than the turning diameter above the bed.

For example, if the lathe has a turning diameter above the bed of 630 mm, this means that you can place an object with a maximum diameter of 630 mm on the lathe and rotate it around the axis. However, the turning diameter above the support may be smaller, for example 500 mm. It is worth remembering that in addition to the turning diameter, other parameters such as distance between centers, turning length and spindle bore are also important when selecting the right lathe for specific machining tasks.

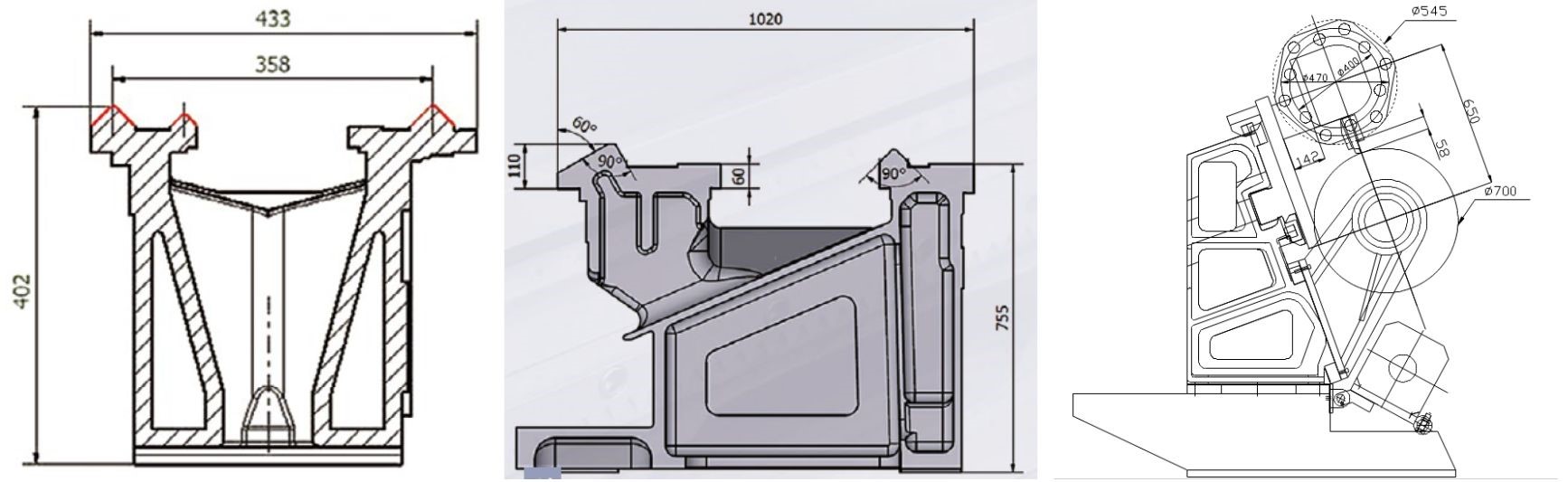

Monolithic bed

A monolithic lathe bed is a structure in which the machine bed is made of a single, cast metal block. This solution is used on all professional FAT lathes, especially on larger and more advanced models. The main advantage of the monolithic lathe bed is its rigidity and stability. The one-piece design provides excellent structural integrity, which translates into higher machining precision. The rigidity of the bed minimizes vibrations and deformations that can affect the accuracy and quality of the machining performed. In addition, the monolithic lathe bed usually has better vibration damping properties compared to other designs. This allows you to achieve a smoother surface of the workpieces and increase the durability of the cutting tools. Read more about production process of beds

However, it is worth noting that the monolithic lathe bed may be more expensive to manufacture and more demanding in terms of transport and installation due to the higher weight and size. Therefore, it is most often used in professional production plants, where the highest quality and precision of machining are required. Ultimately, the choice between monolithic and different type of lathe bed depends on the specific requirements, budget and application of the machine.

FAT HACO lathes are industrial machines that must meet the highest standards in professional machining. In its offer it has lathes with flat bed and slanted bed. Flat bed machines are mainly lathes designed for processing long and heavy production runs. Slant bed lathes are full 5-axis, fully automatic turning and milling centers where the turning diameter is not limited by the carriage. Read more about slant CNC lathe

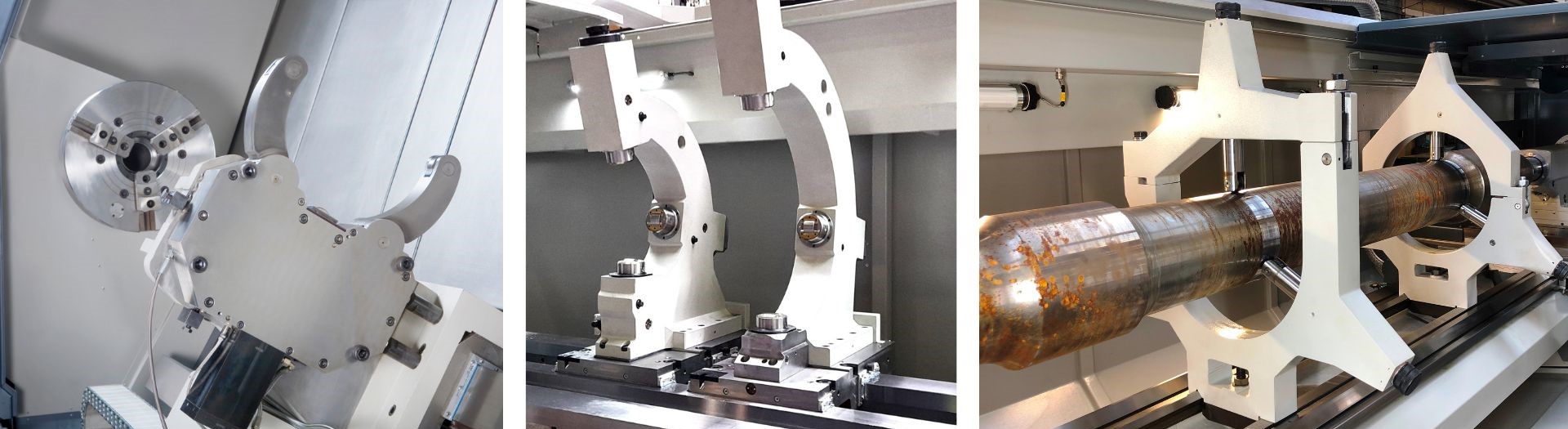

A robust tailstock

With an extended stroke allows the full working range (between tailstock housing and carriage) to be used. Due to this solution, heavy duty machining of any work piece held in the tailstock center is possible. The hydraulically operated quill with a diameter 220 mm (8,7”) is hardened and ground. The Quill has a built-in bearing sleeve with taper socket MT6 for dead center. Quick coupling between the tailstock and cross slide makes positioning time short. Optionally, the tailstock can be equipped with and independent drive. Fat Haco's offer includes manual and hydraulic tailstocks.

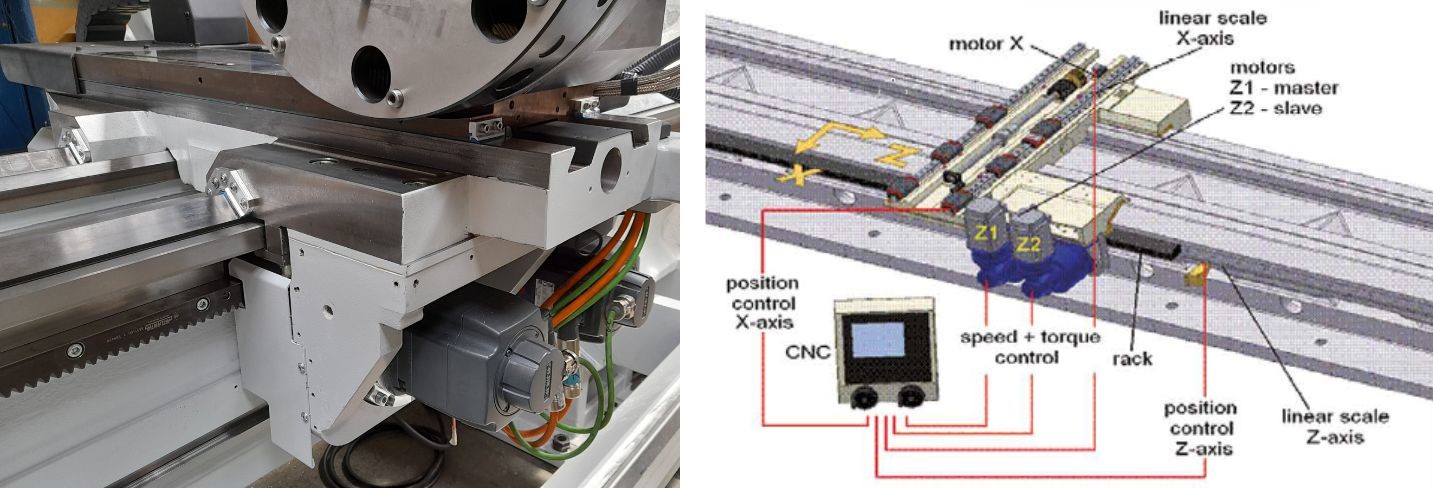

Carriage

A „Master-Slave” drive system is used on lathes with machining lengths longer than 4M, using an automated backlash reduction system and linear scales to achieve very high accuracy. The carriage is driven by two synchronized motors, a gearbox and a rack. Lathes which have shorter machining lenght are equipped with a precise ball screw.

Control Siemens Sinumerik One

FAT lathes with Siemens control allow to work in manual, semi-automatic and full CNC mode. Operator-friendly control system ensures comfortable and effective work.

Main control features:

- easy programming with graphical representation that does not require knowledge of DIN/ISO

- very short programming time

- clear overview of all steps machining process

- simple tool management

- large selection of ready cycles

- machining and measuring

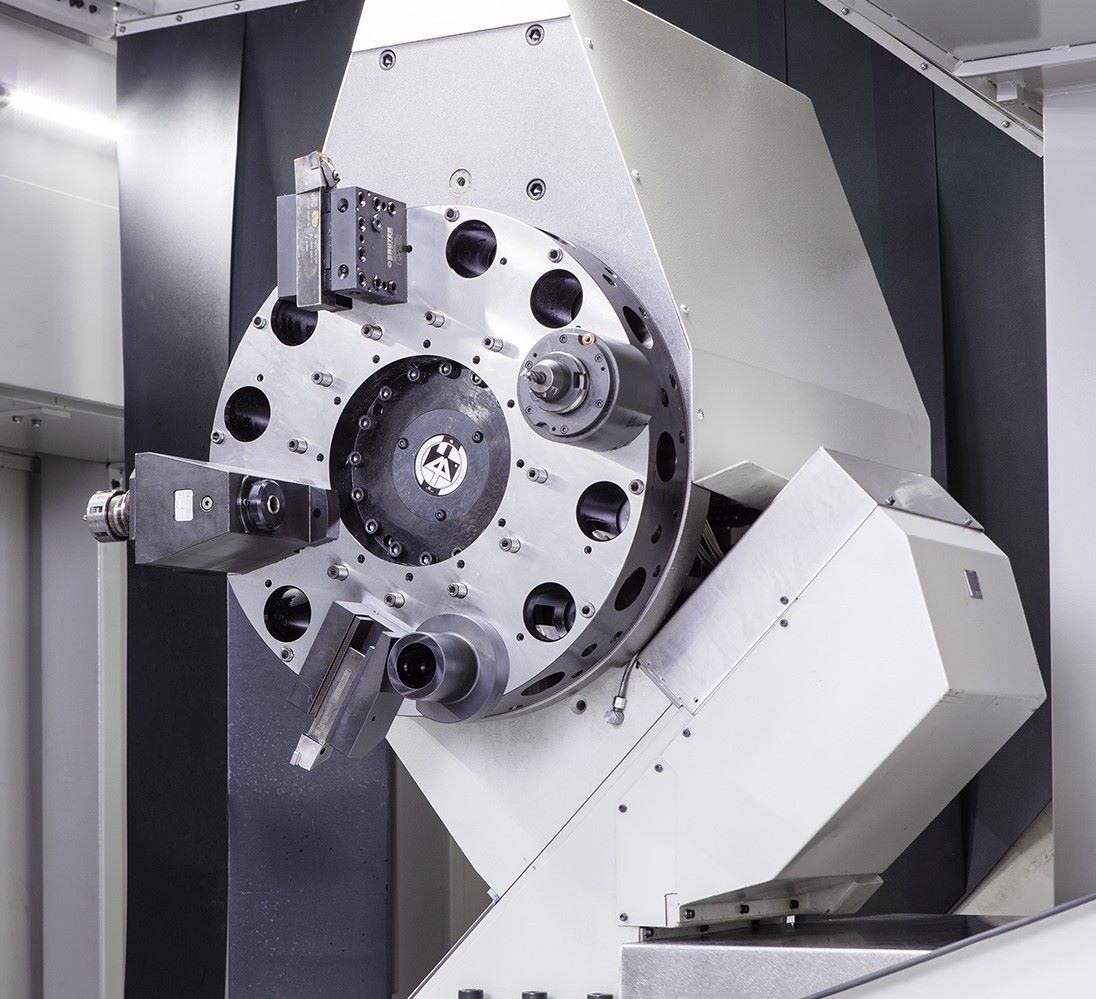

Headstock

The headstock is an important part of the lathe, which contains the drive mechanism of the machine, the spindle and the chuck used to fasten and hold the workpiece, such as the shaft, sleeve or other shape of the workpiece on the lathe. Chucks in FAT HACO lathes are divided into manual and hydraulic. The body of the headstock is made of a uniform cast, mounted on hardened and ground bed guides. Hand scraping of the contact surfaces ensures the best fit and long-term stability of the geometry. High-end spindle bearing ensures the highest machining precision. When choosing a headstock for a lathe, it is important to tailor it to your specific machining needs, taking into account the size of the workpiece, the type of machining and the precision required during the production process. We pay attention to:

- number of spindle ranges

- spindle speed ranges (rpm)

- spindle bore (mm)

- main drive motor power (kW)

Steady rests

A wide range of rests is available to suit different machining applications: manual, hydraulic self-centring, steady or follow rests, C-form, ring rests and other. Steady rests supports facilitate work with long and heavy worpieces as well as thin and light.

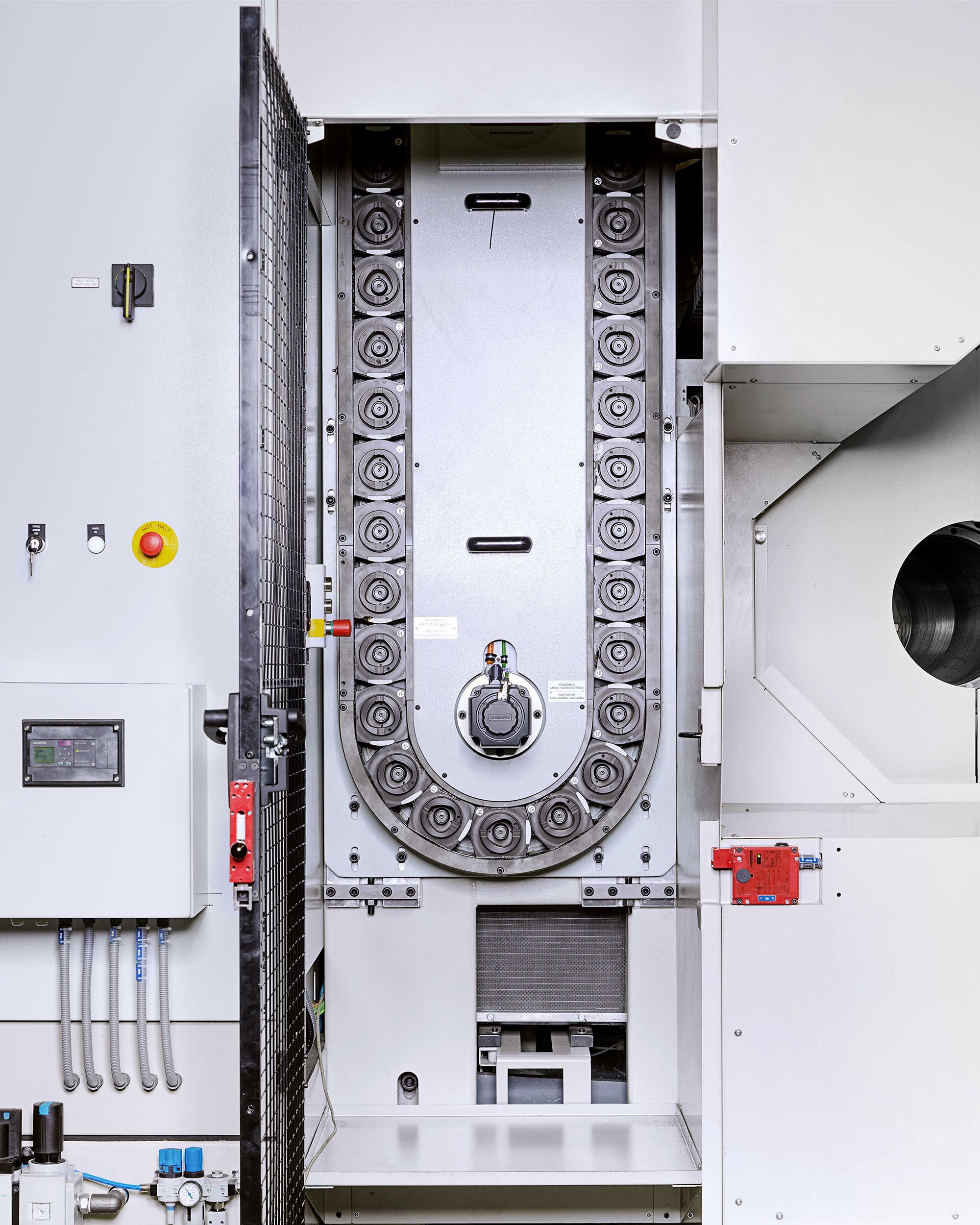

Tool system

The tool system in a lathe is a mechanism that allows manual or automatic change of lathe tools during machining. It aims to streamline the production process and increase the efficiency of the lathe. The basic element of the tool system is the tool turret or tool magazine, where different types of tools are stored. The tool head is usually a rotating disc with tool slots that can be quickly changed during operation. A tool magazine is a cabinet or magazine in which tools are stored and can be retrieved as needed.

The tooling system is integrated into the lathe control system, which controls the tool changing operations. Control can be done manually by the operator or automatically by using CNC (Computer Numerical Control) programs.

The types of tool systems in the lathe are:

- Parat turret - this is a basic tool head that requires manual change of the lathe by the operator.

- Turret head – allow you to mount more tools on a rotating head or disc. This reduces tool change times. Tools can be changed quickly and precisely, which increases the productive time of the lathe.

- Tool magazine – increases production flexibility. The ability to store many types of tools in the tooling system allows you to easily adapt to different machining tasks. The tools are changed automatically on the head depending on the machining program without any physical intervention by the operator.

Advanced tooling systems can monitor tool wear and provide information about the need for replacement, which allows for effective tooling management. The introduction of a tooling system into a lathe can bring significant production benefits, especially when machining large quantities of workpieces or complex turning operations.

Guideways

FAT HACO numerically controlled lathes are available in two-guide and four-guide versions. For a dual-guide lathe, one guide is usually located at the front of the lathe and the other at the back. Both guides are parallel to each other and parallel to the axis of rotation of the material.The presence of two guides allows more stable and precise guidance of the support with the tool head during machining. This allows the two-guide lathe to machinning larger and heavier materials and more accurately control the dimensions and finish quality of the workpieces.

In turn, a four-guide lathe is a machine whose guides are placed parallel to the longitudinal axis of the lathe. The first two guides, on which the support is mounted, allow the tool head to travel without collision with the tailstock and steady rests. This solution facilitates the machining of long, heavy workpieces without the need to machine re-equipment.

Summary

Buying a lathe is an important investment decision that requires taking into account various factors. Here are some key points to consider when buying a lathe:

- Purpose and application: Specify for which specific tasks and processes the lathe will be used. Identify the types of materials, workpiece sizes and machining operations that will be performed. Make sure the lathe has the right capabilities and features to meet your production needs.

- Lathe Capacity: Analyze the size and capacity of the lathe, i. e. its ability to machinning workpieces of certain length, diameter and weight. Make sure the lathe has enough working space and lifting capacity to handle the planned parts.

- Automation and control: Consider whether you need a numerically controlled (CNC) lathe or with additional automation features. CNC lathes enable programmable control and automation of the process, which can increase the precision and efficiency of production.

- Budget: Determine the financial resources available to purchase the lathe and include additional costs such as installation, operator training and service.

- Quality and Reliability: Choose a lathe from a reputable manufacturer that offers high quality and reliability. Read user reviews, examine the reputation of the manufacturer and pay attention to the warranty and availability of spare parts and service. FAT HACO customers reviews

- Safety: Make sure the lathe meets the applicable safety standards and has appropriate protective features such as guards and crash protection.

- Technical support and training: Check if the manufacturer offers technical support, user manuals, and training opportunities for lathe operators. This will help you make optimal use of the machine and keep it in good condition.

Before deciding to buy a lathe, it is worth consulting with our experts and seeking advice from other users on the Polish and foreign markets.

We invite you to contact us:

sales@fathaco.com